Fourth in a series of related articles reviewing the roles that have been identified when working with cranes, explaining the responsibilities, defining the training requirements, as well as outlining the documentation requirements.

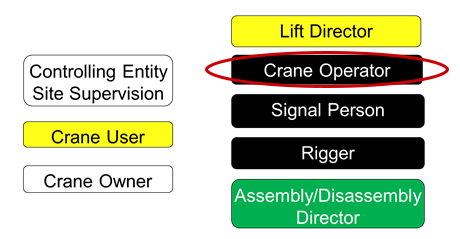

October 2021— As stated in our previous articles, the roles on the left side of the graphic at right are roles that do not have any requirements listed for qualifications (e.g. competent, certified, or qualified). The roles on the right side, however, do have prescribed qualifications and responsibilities.

As stated in our previous articles, the roles on the left side of the graphic at right are roles that do not have any requirements listed for qualifications (e.g. competent, certified, or qualified). The roles on the right side, however, do have prescribed qualifications and responsibilities.

The Crane Operator plays a critical role in the operation of the crane. Many believe that the Crane Operator is the captain of the ship and is responsible for all crane-related things. While this isn’t anywhere near the truth, the Crane Operator does have significant responsibilities and qualification requirements.

In essence, the Crane Operator is responsible from the hook to the wheels—or for tower cranes, the hook to the foundation. This includes knowing the types of site conditions that could adversely affect the operation of the crane and reviewing requirements with the Lift Director. Additionally, the Crane Operator needs to inspect the crane and report needed adjustments or repairs to a designated person. Being able to understand the load chart and determine net capacity as well as being cognizant of all factors that might impact crane capacity are also requirements. The Crane Operator should know standard signals (but is not required to be a qualified signal person) and should understand basic load rigging (but is not required to be a qualified rigger).

Under ASME (which covers all industries), the Crane Operator is required to be a qualified individual. Qualified “means a person who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training and experience, successfully demonstrated the ability to solve/resolve problems relating to the subject matter, the work, or the project.” Further, ASME defined content areas that the Crane Operator must demonstrate knowledge, skills and abilities. This content is broken down into a written exam and a practical exam on the crane type the operator is operating. ASME also defined physical qualifications for the operator. In 2021, ASME modified the physical requirements to be similar to the DOT physical requirements for CDL licenses.

In 2018, OSHA released the last portion of the Federal Crane Rule for Construction, which has a similar but different qualification process for crane operators. OSHA defined three critical elements:

- An operator training process

- The licensing/certification requirements

- An employer evaluation process

For OSHA, training + certification + evaluation = qualification.

If an operator has not been certified AND evaluated, they are an “operator-in-training” and may only be assigned tasks within the operator-in training’s ability. In critical lifting situations such as operations near energized power lines, personnel hoisting or multiple equipment lifts, the trainee must be certified. The operator’s trainer must be an employee or agent of the operator-in-training’s employer and have the knowledge, training, and experience necessary to direct the operator-in-training on the equipment in use. Retraining is based on the performance of the operator or an evaluation indicating training is necessary.

For certification, OSHA requires that the certification is performed by a nationally recognized accrediting agency. There have been several changes over the past several years as to which organizations are accredited. For the most up-to-date information, the NCCCO Foundation provides an Accredited Certifier Directory. Certification can be by type or by type and capacity. In cases where a nationally accredited certification is not available, OSHA directs that a “most similar” certification should be utilized. The NCCCO Foundation has created a Crane Type Advisory Group (CTAG) which identifies the most similar certifications to be used.

OSHA defined crane operator evaluation as where the employer must ensure that each operator is qualified by a demonstration of:

- The skills and knowledge, as well as the ability to recognize and avert risk, necessary to operate the equipment safely, including those specific to the safety devices, operational aids, software, and the size and configuration of the equipment.

- Size and configuration include, but are not limited to, lifting capacity, boom length, attachments, luffing jib, and counterweight configuration.

- The ability to perform the hosting activities required for assigned work, including, if applicable, blind lifts, personnel hoisting, and multi-crane lifts.

Said more simply, the evaluation needs to show skills and knowledge related to the crane as well as to the work. It is very important for crane operator employers to have a plan and a strategy for complying with these detailed requirements. Differences in crane type, manufacturer, software systems, attachments, etc. should be considered when differentiating evaluations. Further, the type of work should be differentiated as well. Some organizations have defined “standard” lifts and have unique evaluations for “non-standard” lifts such as working around power lines, personnel hoisting, critical lifts, multi-crane lifts, and multi-load line lifts.

Lastly, and perhaps most importantly, the evaluation documentation must contain the operator’s name, evaluator’s name and signature, the date, the make, model, and configuration of the equipment. It also must be available at the worksite.

By Thom Sicklesteel, CEO of the National Commission for the Certification of Crane Operators (NCCCO), a voting member of ASME B30.5, and an member on B30.

View the other articles in this series: